In the glass processing industry, every piece of custom glass is unique.

To ensure that customers receive accurate and reasonable quotations, Saida Glass emphasizes thorough communication with clients to understand every detail of the product.

1. Product Dimensions and Glass Thickness

Reason: The cost, processing difficulty, and transportation method of glass are directly affected by its size and thickness. Larger or thicker glass is more difficult to process, has a higher breakage rate, and requires different cutting, edging, and packaging methods.

Example: A 100×100 mm, 2mm thick glass and a 1000×500 mm, 10mm thick glass have completely different cutting difficulties and costs.

2. Application/Use

Reason: The application determines the performance requirements of the glass, such as heat resistance, scratch resistance, explosion resistance, and anti-reflection. Different applications require different materials or special treatments.

Example: Lighting glass requires good light transmission, while industrial protective glass may require tempering or explosion-proof treatment.

3. Edge Grinding Type

Reason: Edge treatment affects safety, feel, and aesthetics. Different edge grinding methods (such as straight edge, chamfered edge, rounded edge) have different processing costs.

Example: Rounded edge grinding is more time-consuming and costly than straight edge grinding, but it provides a safer feel.

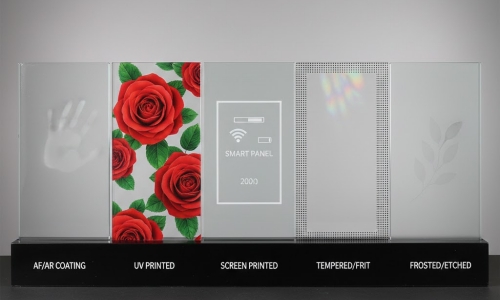

4. Surface Treatment (Coatings, Printing, etc.)

Reason: Surface treatment affects function and appearance, for example:

- Anti-fingerprint/anti-reflective coatings

- UV printing or screen printing patterns

- Decorative effects after coating or tempering

Different treatments have a significant impact on process and cost.

5. Packaging Requirements

Reason: Glass is fragile, and the packaging method determines transportation safety and cost. Special customer requirements (such as shockproof, moisture-proof, single-piece packaging) will also affect the quotation.

6. Quantity or Annual Usage

Reason: Quantity directly affects production scheduling, material procurement, and cost. Large orders can utilize automated production lines, while single pieces or small batches may require manual processing, resulting in significant cost differences.

7. Required Delivery Time

Reason: Urgent orders may require overtime or expedited production, increasing costs. A reasonable delivery time allows for optimized production scheduling and logistics arrangements, lowering the quotation.

8. Drilling or Special Hole Requirements

Reason: Drilling or hole processing increases the risk of breakage, and different hole diameters, shapes, or positional accuracy requirements will affect the processing technology and cost.

9. Drawings or Photos

Reason: Drawings or photos can clearly define dimensions, tolerances, hole positions, edge shapes, printing patterns, etc., avoiding communication errors. For complex or customized products, drawings are the basis for quotation and production.

If the customer is temporarily unable to provide all the information, our professional team will also help determine the specifications or recommend the best solution based on the available information.

Through this process, Saida Glass not only ensures that every quotation is accurate and transparent but also guarantees product quality and customer satisfaction. We believe that details determine quality, and communication builds trust.

Do you want to customize glass for your products? Please contact us at sales@saideglass.com

Post time: Dec-30-2025