I. Core Definition of Deep Processing

Glass deep processing refers to the secondary processing of raw flat glass (float glass) directly supplied by glass manufacturers. Through a series of technological optimizations, it enhances the safety performance, functional characteristics, or aesthetic appeal of glass, ultimately meeting the personalized needs of multiple fields such as construction, home furnishing, automotive, and electronics. After deep processing, the added value of raw glass can be increased several times, while adapting to the core demands for safety, energy efficiency, and intelligence in modern scenarios.

II. Main Processing Procedures

(I) Basic Processing Stages

- Cutting: Process large-sized raw glass into specific shapes and dimensions according to customer requirements, including straight-line cutting, CNC numerical control special-shaped cutting, and drilling.

- Edge Grinding/Chamfering: Grind the edges of cut glass into straight, round, beveled, or other profiles to eliminate sharp edges, ensuring both safety and aesthetic appeal.

- Cleaning & Drying: Remove impurities, oil stains, and dust from the glass surface to provide a clean base for subsequent processes such as coating and lamination, ensuring processing adhesion.

(II) Strengthening & Functional Processing Stages

- Tempering (Strengthening)

- Physical Tempering: Heat glass to its softening point and then rapidly cool it, forming a compressive stress layer on the surface. This increases strength by 4-5 times, and the glass breaks into granular fragments (classified as safety glass).

- Chemical Tempering: Enhance strength through ion exchange technology, suitable for thin glass or special-shaped glass processing.

- Coating

- Low-E Coating: Apply metal or oxide layers via vacuum magnetron sputtering to reflect infrared rays, achieving energy saving and thermal insulation.

- Solar Control Coating: Reduce solar radiant heat entering indoor spaces and adjust light transmission.

- Self-Cleaning Coating: Utilize photocatalytic principles to decompose surface stains, reducing maintenance costs.

- Lamination: Sandwich PVB, EVA, or other interlayers between two glass sheets, bonding them under high temperature and pressure. The glass does not splinter when broken, offering explosion-proof and protective performance.

- Insulated Glass Production: Separate two or more glass sheets with spacers and fill the cavity with dry air or inert gas (e.g., argon) to significantly improve sound and thermal insulation.

(III) Decoration & Forming Processing Stages

- Printing/Decoration: Include screen printing (for color patterns or logos), digital printing (for complex personalized designs), and etching/sandblasting (for frosted effects).

- Bending/Thermal Bending: Heat glass to soften it and press it into curved or arched shapes to meet special design requirements.

III. Core Types of Deep-Processed Glass & Application Scenarios

| Glass Type | Core Processing Technology | Typical Application Scenarios |

|---|---|---|

| Tempered Glass | Physical/Chemical Tempering | Building doors/windows, curtain walls, shower enclosures, furniture panels |

| Laminated Glass | High-temperature & high-pressure bonding with PVB/EVA interlayers | Bank explosion-proof glass, building skylights, high-altitude curtain walls |

| Low-E Glass | Vacuum Magnetron Sputtering Coating | Energy-saving building doors/windows, refrigerator doors, high-end residential curtain walls |

| Insulated Glass | Glass + Spacers + Sealant + Dry Gas Filling | High-rise building doors/windows, airport terminals, residential soundproof windows |

| Ceramic Fritted Glass | Screen Printing + Tempering | Building exterior decoration, subway stations, commercial complex curtain walls |

| Fire-Resistant Glass | Lamination with special gel/Cesium-Potassium treatment | Building fire compartments, safety exits, equipment room partitions |

| Smart Tinting Glass | Lamination with PDLC electrically controlled dimming film | Office partitions, hotel rooms, high-end meeting room privacy glass |

IV. Key Deep Processing Equipment

| Processing Stage | Core Equipment List |

|---|---|

| Cutting | CNC automatic cutting table, CNC special-shaped cutting machine |

| Edge Grinding | Straight-line edge grinder, special-shaped edge grinder, chamfering machine |

| Tempering | Horizontal tempering furnace, vertical tempering furnace, chemical tempering equipment |

| Coating | Vacuum magnetron sputtering coating production line |

| Lamination | Autoclave, vacuum pre-presser, interlayer laminating equipment |

| Insulated Glass | Automatic gas filling and sealing system, spacer installation machine, dry gas filling equipment |

| Decoration | Screen printing machine, digital printer, etching/sandblasting equipment |

| Thermal Bending | Glass bending furnace, curved pressing mold |

V. Quality Control Standards

(I) Safety Standards

- Tempered Glass: Complies with GB 15763.2 National Standard

- Laminated Glass: Complies with GB 15763.3 National Standard

- Fire-Resistant Glass: Complies with corresponding fire protection product safety certification standards

(II) Performance Standards

- Optical Performance: Meeting standards for visible light transmittance, UV blocking rate, infrared reflectance, etc.

- Durability: Damp-heat resistance test, aging resistance test (e.g., dew point detection for insulated glass)

- Process Precision: Dimensional tolerance, edge flatness, coating adhesion, etc., complying with industry specifications

VI. Core Application Fields

(I) Construction Field

- Main Products: Curtain wall glass, energy-saving door/window glass, skylight glass, fire-resistant partition glass, decorative ceramic fritted glass

- Core Requirements: Explosion-proof safety, energy saving & thermal insulation, sound insulation, aesthetic decoration

(II) Home Furnishing Field

- Main Products: Tempered coffee table glass, bathroom partition glass, mirror glass, custom decorative glass

- Core Requirements: Shatterproof safety, easy cleaning, personalized design

(III) Automotive Field

- Main Products: Windshields, side windows, sunroofs, rearview mirror glass

- Core Requirements: Explosion-proof & anti-splintering, high light transmittance, strong impact resistance

(IV) Electronics Field

- Main Products: Mobile phone cover glass, TV panel glass, smart device touch glass

- Core Requirements: High strength, high light transmittance, scratch resistance

(V) Photovoltaic Field

- Main Products: Solar cell encapsulation glass

- Core Requirements: High light transmittance, excellent weather resistance, strong insulation performance

VII. Principles of Process Selection

Enterprises should select corresponding processing technology combinations based on the core needs of end-use scenarios (e.g., safety, energy efficiency, privacy, shape), while strictly adhering to relevant quality standards to ensure that product performance is highly compatible with application scenarios.

Post time: Dec-17-2025

Send Inquiry to Saida Glass

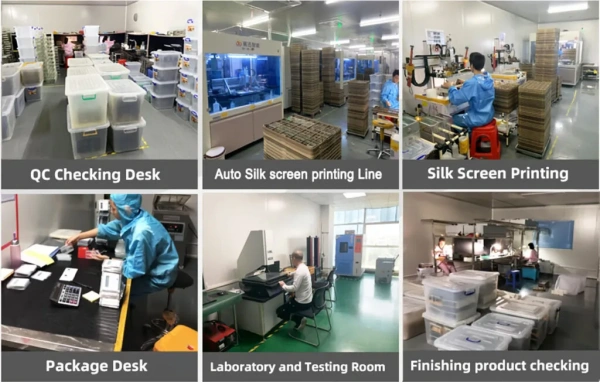

We are Saida Glass, a professional glass deep-processing manufacturer. We process purchased glass into customized products for electronics, smart devices, home appliances, lighting, and optical applications etc.

To get an accurate quotation, please provide:

● Product dimensions & glass thickness

● Application / usage

● Edge grinding type

● Surface treatment (coating, printing, etc.)

● Packaging requirements

● Quantity or annual usage

● Required delivery time

● Drilling or special hole requirements

● Drawings or photos

If you don’t have all the details yet:

Just provide the information you have.

Our team can discuss your requirements and help

you determine specifications or suggest suitable options.

Send your message to us:

-

Send Inquiry

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Send your message to us:

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur