I. Tlhaloso ea Motheo ea Ts'ebetso e Tebileng

Ts'ebetso e tebileng ea khalase e bolela ts'ebetso ea bobeli ea khalase e tala e bataletseng (khalase e phaphametseng) e fanoang ka kotloloho ke bahlahisi ba khalase. Ka letoto la lintlafatso tsa theknoloji, e ntlafatsa ts'ebetso ea polokeho, litšobotsi tsa ts'ebetso, kapa botle ba khalase, qetellong e fihlela litlhoko tsa motho ka mong tsa masimo a mangata a kang kaho, thepa ea ka tlung, likoloi le lisebelisoa tsa elektroniki. Kamora ts'ebetso e tebileng, boleng bo eketsehileng ba khalase e tala bo ka eketsoa ka makhetlo a 'maloa, ha bo ntse bo ikamahanya le litlhoko tsa mantlha tsa polokeho, ts'ebetso e ntle ea matla le bohlale maemong a sejoale-joale.

II. Mekhoa e Meholo ea Ts'ebetso

(I) Mehato ea Motheo ea Ts'ebetso

- Ho seha: Sila khalase e tala e kgolo ka boholo bo boholo ho ya ka ditlhoko tsa bareki, ho kenyeletswa le ho seha ka mola o otlolohileng, ho seha ka sebopeho se ikgethang sa taolo ya dipalo ya CNC, le ho tjheka.

- Ho Sila/Ho Hlwekisa Moeli: Sila mathoko a khalase e khaotsoeng hore e be liprofaele tse otlolohileng, tse chitja, tse betliloeng, kapa tse ling ho tlosa mathoko a bohale, ho netefatsa polokeho le botle.

- Ho Hloekisa le ho Omisa: Tlosa litšila, matheba a oli le lerōle holim'a khalase ho fana ka motheo o hloekileng bakeng sa lits'ebetso tse latelang tse kang ho koahela le ho lamination, ho netefatsa hore ts'ebetso ea ho e lokisa e khomarela.

(II)Mehato ea ho Matlafatsa le ho Sebetsa

- Ho Matlafatsa (Ho Matlafatsa)

- Tekanyo ea 'Mele: Futhumatsa khalase ho fihlela moo e nolofalang teng ebe u e pholisa ka potlako, u etse lera la khatello le hatellang holim'a metsi. Sena se eketsa matla ka makhetlo a 4-5, 'me khalase e robeha likotoana tse nang le granular (tse khetholloang e le khalase ea polokeho).

- Ho Tekanya Lik'hemik'hale: Ho eketsa matla ka theknoloji ea phapanyetsano ea li-ion, e loketseng khalase e tšesaane kapa ts'ebetso ea khalase e bōpehileng joaloka e khethehileng.

- Ho koahela

- Seaparo sa Low-E: Kenya lera la tšepe kapa oxide ka vacuum magnetron sputtering ho bonahatsa mahlaseli a infrared, ho fihlella poloko ea matla le ho thibela mocheso.

- Sekoahelo sa Taolo ea Letsatsi: Fokotsa mocheso o matla oa letsatsi o kenang libakeng tsa ka tlung 'me u lokise phetiso ea leseli.

- Ho Itlhoekisa: Sebelisa melao-motheo ea photocatalytic ho bolisa matheba a bokaholimo, ho fokotsa litšenyehelo tsa tlhokomelo.

- Lamination: Sandwich PVB, EVA, kapa mealo e meng pakeng tsa maqephe a mabedi a khalase, e a kopanya tlas'a mocheso o phahameng le khatello. Khalase ha e petsohe ha e robehile, e fana ka ts'ebetso e sireletsang le e thibelang ho phatloha.

- Tlhahiso ea Khalase e Sirelelitsoeng: Arola maqephe a khalase a mabeli kapa ho feta ka li-spacer 'me u tlatse sekoti ka moea o omileng kapa khase e sa sebetseng (mohlala, argon) ho ntlafatsa molumo le ho thibela mocheso haholo.

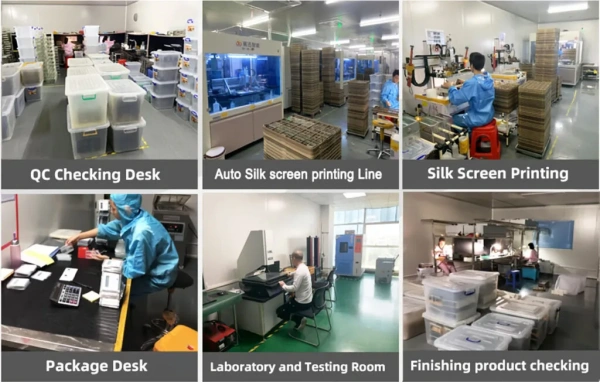

(III) Mehato ea ho Hlophisa le ho Etsa Mekhabiso

- Khatiso/Mekhabiso:Kenyelletsa khatiso ea skrine (bakeng sa lipaterone tsa mebala kapa matšoao), khatiso ea dijithale (bakeng sa meralo e rarahaneng e etselitsoeng motho ka mong), le ho fata/ho qhaqha lehlabathe (bakeng sa litlamorao tse nang le serame).

- Ho kobeha/Ho kobeha ka mocheso: Futhumatsa khalase ho e nolofatsa le ho e hatella hore e be dibopeho tse kobehileng kapa tse nang le mehele e mengata ho fihlela ditlhoko tse ikgethang tsa moralo.

III. Mefuta ea Bohlokoa ea Liketsahalo tsa Khalase le Tšebeliso tse Tebileng

| Mofuta oa Khalase | Theknoloji ea Ts'ebetso ea Core | Maemo a Tloaelehileng a Kopo |

|---|---|---|

| Khalase e Bonolo | Tekanyo ea 'Mele/Lik'hemik'hale | Mamati/lifensetere tsa moaho, mabota a likharetene, matlo a ho hlapela, liphanele tsa thepa ea ka tlung |

| Khalase e Laminated | Tlamahano ea mocheso o phahameng le khatello e phahameng e nang le likarolo tse kopaneng tsa PVB/EVA | Khalase e sa phatloheng ke lebopong, mabone a kaho, mabota a likharetene a bophahamo bo phahameng |

| Khalase e Tlase ea E | Sekoahelo sa ho Koahela ka Letsoho la Magnetron | Mamati/lifensetere tsa moaho tse bolokang matla, mamati a sehatsetsi, mabota a masela a bolulo a maemo a holimo |

| Khalase e nang le mocheso o feteletseng | Khalase + Li-Spacer + Sealant + Ho Tlatsa Khase e Omileng | Mamati/lifensetere tsa meaho e melelele, liteishene tsa boema-fofane, lifensetere tse sa keneleng molumo tsa bolulo |

| Khalase e halikiloeng ka letsopa | Khatiso ea Sekirini + Tempering | Mokhabiso oa kantle oa moaho, liteishene tsa terene e tsamaeang ka tlas'a lefatše, mabota a masela a khoebo a rarahaneng |

| Khalase e Hanelang Mollo | Lamination ka kalafo e khethehileng ea gel/Cesium-Potassium | Libaka tsa mollo tsa moaho, menyako ea polokeho, likarolo tsa kamore ea lisebelisoa |

| Khalase e Bohlale ea ho Tintša | Lamination e nang le filimi ea PDLC e laoloang ka motlakase e fifatsang | Likarolo tsa liofisi, likamore tsa lihotele, khalase ea lekunutu ea kamore ea liboka ea maemo a holimo |

IV. Lisebelisoa tsa Ts'ebetso e Tebileng ea Bohlokoa

| Mokhahlelo oa Ts'ebetso | Lethathamo la Lisebelisoa tsa Bohlokoa |

|---|---|

| Ho seha | Tafole ea ho itšeha ea CNC ka boiketsetso, mochini oa ho itšeha o bōpehileng joaloka CNC o ikhethang |

| Ho Sila ka Moeli | Sesepa sa mathoko se otlolohileng, sesepa sa mathoko se bōpehileng joaloka se khethehileng, mochini oa ho qhaqha |

| Ho leka-lekanya | Sebōpi sa ho futhumatsa se otlolohileng, sebōpi sa ho futhumatsa se otlolohileng, lisebelisoa tsa ho futhumatsa lik'hemik'hale |

| Ho koahela | Mohala oa tlhahiso ea ho roala o nang le lephaka oa magnetron sputtering |

| Lamination | Autoclave, vacuum pre-presser, lisebelisoa tsa laminating tse kenellang |

| Khalase e nang le mocheso o feteletseng | Sistimi ea ho tlatsa le ho tiisa khase ka boiketsetso, mochini oa ho kenya sebaka, lisebelisoa tsa ho tlatsa khase tse omileng |

| Mokhabiso | Mochini oa khatiso ea skrine, printa ea dijithale, lisebelisoa tsa ho betla/ho phunya lehlabathe |

| Ho Kobeha ha Thermal | Khalase e kobehileng sebōpi, hlobo e kobehileng e hatellang |

V. Maemo a Taolo ea Boleng

(I) Maemo a Polokeho

- Khalase e Tebileng: E latela Maemo a Naha a GB 15763.2

- Khalase e Laminated: E latela Maemo a Naha a GB 15763.3

- Khalase e Hanelang Mollo: E latela maemo a nepahetseng a setifikeiti sa polokeho ea sehlahisoa sa tšireletso ea mollo

(II) Maemo a Tshebetso

- Tshebetso ya Optical: Ho fihlella maemo a phetiso ya lesedi le bonahalang, sekgahla sa ho thibela UV, kganya ya infrared, jj.

- Ho tšoarella: Teko ea ho hanyetsa mongobo le mocheso, teko ea ho hanyetsa botsofali (mohlala, ho lemoha ntlha ea phoka bakeng sa khalase e nang le insulation)

- Ts'ebetso e nepahetseng: Ho mamellana ka tekanyo, ho batalla ha bohale, ho khomarela ho koahela, jj., ho latela litlhaloso tsa indasteri

VI. Masimo a Kopo ea Motheo

(I) Lebala la Kaho

- Lihlahisoa tse ka Sehloohong: Khalase ea lebota la lesira, khalase ea monyako/fensetere e bolokang matla, khalase ea skylight, khalase ea karohano e sa cheng, khalase e khabisitsoeng ea ceramic fried

- Litlhoko tsa Bohlokoa: Polokeho e thibelang ho phatloha, ho boloka matla le ho thibela mocheso, ho thibela molumo, mokhabiso oa botle

(II) Sebaka sa Thepa ea Lapeng

- Lihlahisoa tse ka Sehloohong: Khalase ea tafole ea kofi e bonolo, khalase ea karohano ea kamore ea ho hlapela, khalase ea seipone, khalase e khabisitsoeng ka mokhoa o ikhethileng

- Litlhoko tsa mantlha: Polokeho e sa robeheng, ho hlwekisa habonolo, moralo o ikhethileng

(III) Lefapha la Likoloi

- Lihlahisoa tse ka Sehloohong: Lifensetere tsa ka morao, lifensetere tse ka thoko, marulelo a letsatsi, khalase ea seipone se ka morao

- Litlhoko tsa Bohlokoa: Ha e phatlohe ebile ha e phatlohe, e fetisa leseli le leholo, e hanyetsa tšusumetso e matla

(IV) Lefapha la Elektroniki

- Lihlahisoa tse ka Sehloohong: Khalase ea sekoahelo sa mohala oa selefouno, khalase ea phanele ea TV, khalase ea ho ama ea sesebelisoa se bohlale

- Litlhoko tsa mantlha: Matla a phahameng, phetiso e phahameng ea leseli, ho hanyetsa ho ngoapa

(V) Tšimo ea Photovoltaic

- Lihlahisoa tse ka Sehloohong: Khalase ea ho kenya lisele tsa letsatsi

- Litlhoko tsa mantlha: Phetiso e phahameng ea leseli, khanyetso e ntle ea boemo ba leholimo, ts'ebetso e matla ea ho thibela ho ruruha

VII. Melao-motheo ea Khetho ea Ts'ebetso

Likhoebo li lokela ho khetha metsoako e tsamaellanang ea theknoloji ea ts'ebetso ho latela litlhoko tsa mantlha tsa maemo a tšebeliso ea qetellong (mohlala, polokeho, ts'ebetso e ntle ea matla, lekunutu, sebopeho), ha li ntse li khomarela ka tieo litekanyetso tse nepahetseng tsa boleng ho netefatsa hore ts'ebetso ea sehlahisoa e lumellana haholo le maemo a ts'ebeliso.

Nako ea poso: Tshitwe-17-2025

Romela Dipotso ho Saida Glass

Re Saida Glass, moetsi oa litsebi oa ho sebetsana le khalase ka botebo. Re sebetsana le khalase e rekiloeng hore e be lihlahisoa tse ikhethileng bakeng sa lisebelisoa tsa elektroniki, lisebelisoa tse bohlale, lisebelisoa tsa lapeng, mabone le lits'ebetso tsa optical jj.

Ho fumana khotheishene e nepahetseng, ka kopo fana ka:

● Litekanyo tsa sehlahisoa le botenya ba khalase

● Tšebeliso / tšebeliso

● Mofuta oa ho sila ka bohale

● Kalafo ea bokaholimo (ho koahela, ho hatisa, jj.)

● Litlhoko tsa ho paka

● Palo kapa tšebeliso ea selemo le selemo

● Nako e hlokahalang ea ho tlisa

● Litlhoko tsa ho cheka kapa tsa masoba a khethehileng

● Litšoantšo kapa linepe

Haeba ha o so fumane lintlha tsohle:

Fana feela ka tlhahisoleseding eo u nang le eona.

Sehlopha sa rona se ka buisana ka litlhoko tsa hau le thuso

o etsa qeto ka litlhaloso kapa o fana ka maikutlo a dikgetho tse loketseng.

Romella molaetsa oa hau ho rona:

-

Romela Dipatlisiso

-

Mohala

-

Imeile

-

WhatsApp

-

WeChat

Romella molaetsa oa hau ho rona:

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur