Inkqubela phambili yethu ixhomekeke koomatshini ababalaseleyo, italente egqwesileyo kunye namandla etekhnoloji aqinisiweyo rhoqo ngexabiso elithengiswayo. Ifestile yeglasi yeBorosilicate yaseTshayina, Umgangatho ophezulu kunye namaxabiso akhuphisanayo enza iimveliso zethu kunye nezisombululo zixabise igama eliphezulu kulo lonke ilizwe.

Inkqubela yethu ixhomekeke koomatshini ababalaseleyo, iziphiwo ezibalaseleyo kunye namandla etekhnoloji aqinisiweyo rhoqoIglasi yeBorosilicate ecacileyo yaseTshayina, Iglasi yePryex, Isebe lethu le-R&D lisoloko liyila ngeengcinga ezintsha zefashoni ukuze sikwazi ukwazisa iindlela zefashoni ezihlaziyiweyo inyanga nenyanga. Iinkqubo zethu zolawulo lwemveliso ezingqongqo zihlala ziqinisekisa iimpahla ezizinzileyo nezisemgangathweni ophezulu. Iqela lethu lezorhwebo libonelela ngeenkonzo ezifanelekileyo ngexesha elifanelekileyo. Ukuba kukho nawuphi na umdla kunye nemibuzo malunga neemveliso kunye nezisombululo zethu, khumbula ukunxibelelana nathi ngexesha. Singathanda ukuseka ubudlelwane beshishini nenkampani yakho ehloniphekileyo.

IIMBONAKALO

– 3.3 I-Coefficient yoKwandiswa koBushushu

– Ukumelana nobushushu obuphezulu ngenxa yeekhemikhaliuzinzo

–Imelana nokukrweleka kakhulu, ingangeni manzi kwaye imelana nomlilo

–Ukuthe tye nokugudileyo okugqibeleleyo

–Isiqinisekiso somhla wokuhanjiswa ngexesha elifanelekileyo

–Ingcebiso yomntu ngamnye kunye nesikhokelo sobungcali

–Imilo, ubungakanani, isiphelo kunye noyilo zingenziwa ngokwezifiso ngokwesicelo

–Izinto ezichasene nokukhanya/ezichasene nokukhanya/ezichasene neminwe/ezichasene neentsholongwane ziyafumaneka apha

Ingxelo yezinto zeglasi zeBorosilicate ephezulu

| 密度 (Ukuxinana) | 2.30g/cm² |

| 硬度 (Ukuqina) | 6.0′ |

| 弹性模量 (Elasticity Modulus) | 67KNmm – 2 |

| 抗张强度(Amandla okuqina) | 40 – 120Nmm – 2 |

| 泊松比(Poisson Ratio) | 0.18 |

| 热膨胀系数 (20-400°C)(I-Coefficient yoKwandiswa kweThermal) | (3.3)*10`-6 |

| 导热率比热(90°C)(Ukwenziwa kobushushu obukhethekileyo) | 1.2W*(M*K`-1) |

| 折射率 (Refractive Index) | 1.6375 |

| 比热 (Ubushushu obukhethekileyo) (J/KG) | 830 |

| 熔点 (Indawo yokunyibilika) | 1320°C |

| 软化点 (Indawo yokuthambisa) | 815°C |

| 连续工作温度/使用寿命 (Ubushushu bokusebenza ngokuqhubekayo/uBomi beNkonzo) | 150°C |

| ≥120000h(-60°C-150°C) | 200°C |

| ≥90000h(-60°C-200°C) | 280°C |

| ≥620000h(-60°C-280°C) | 370°C |

| ≥30000h | 520°C |

| ≥130000h | |

| 抗热冲击(Thermal Shock) | ≤350°C |

| 抗冲击强度(Amandla empembelelo) | ≥7J |

| 主要化学成分%含量(Ukwakheka kweMichiza engundoqo % Umxholo) | |

| I-SiO2 | 80.40% |

| Fe203 | 0.02% |

| I-Ti02 | 1.00% |

| B203 | 12.50% |

| I-Na20+K20 | 4.20% |

| FE | 0.02% |

| 耐水性 (Ukunyamezela Amanzi) | HGB 1级 (HGB 1) |

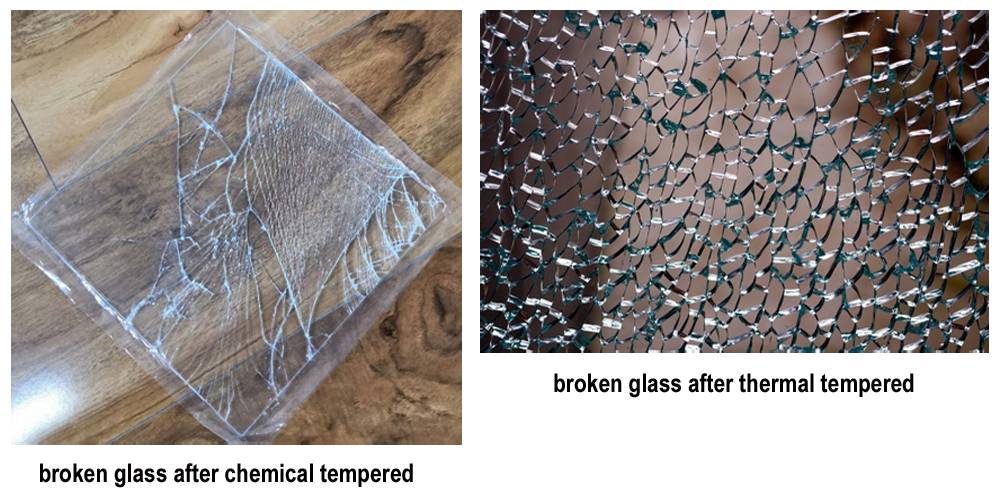

Yintoni iglasi yokhuseleko?

Iglasi eqinisiweyo okanye eqinisiweyo luhlobo lweglasi yokhuseleko ecutshungulwa ngonyango olulawulwayo lobushushu okanye lweekhemikhali ukuze kwandiswe

amandla ayo xa ethelekiswa neglasi eqhelekileyo.

Ukufudumala kubeka umphezulu ongaphandle kwingcinezelo kwaye umphezulu uxinezeleke.

ISISHWANKATHELO SEFEKTRI

UKUTYELELA KWABATHENGI NOKUBUZA IMPENDULO

Zonke izixhobo ezisetyenzisiweyo IHAMBANA NE-ROHS III (UHLELO LWASEYUROPHU), I-ROHS II (UHLELO LWASETSHAYINA), I-REACH (UHLELO LWANGOKU)

IFEKTHI YETHU

UMGCA WETHU WEVELISO NENDLU YOKUGCINA

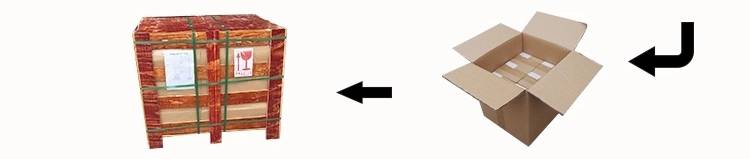

Ifilimu yokukhusela elaminating — Ukupakisha ikotoni yePearl — Ukupakisha iphepha leKraft

UHLOBO LWESITHATHU LOKUKHETHA UKUSONGA

Iphakheji yetyala leplywood yokuthumela ngaphandle — Iphakheji yebhokisi yephepha yokuthumela ngaphandle