Tsoelo-pele ea rona e itšetlehile ka mechine e phahameng, litalenta tse ikhethang le matla a theknoloji a ntseng a matlafala ka theko e kholo Chaena Borosilicate Glass Window, Boleng bo holimo le litefiso tse hlōlisanang li etsa hore lihlahisoa le litharollo tsa rona li ananele lebitso le phahameng ho potoloha lentsoe.

Tsoelo-pele ea rona e itšetlehile ka mechine e phahameng, litalenta tse ikhethang le matla a theknoloji a ntseng a matlafatsoa bakeng saChina e Bonaletsang ea Borosilicate Glass, Khalase ea Pryex, Lefapha la rona la R&D le lula le rala ka mehopolo e mecha ea feshene e le hore re ka hlahisa mekhoa ea feshene ea morao-rao khoeli le khoeli. Mekhoa ea rona e tiileng ea tsamaiso ea tlhahiso e lula e netefatsa thepa e tsitsitseng le ea boleng bo holimo. Sehlopha sa rona sa khoebo se fana ka lits'ebeletso tse sebetsang ka nako le ka katleho. Haeba ho na le thahasello le lipotso mabapi le lihlahisoa le litharollo tsa rona, hopola ho ikopanya le rona ka nako. Re ka rata ho theha kamano ea khoebo le k'hamphani ea hau e hlomphehang.

LIKAROLOANA

– 3.3 Katoloso ea Thermal Coefficient ea 3.3

– Ho hanyetsa mocheso o phahameng ka lebaka la lik'hemik'halebotsitso

–E hanela ho ngoapa haholo, e sa keneleng metsi le e hanelang malakabe

–Ho batalla le ho boreleli ka ho phethahetseng

–Tiisetso ea letsatsi la ho tlisa ka nako

–Boemeli ba motho ka mong le tataiso ea setsebi

–Sebopeho, boholo, finsh le moralo li ka fetoloa ho latela kopo

–E thibelang khanya/E thibelang ho phatsima/E thibelang ho phatsima ha menoana/E thibelang likokoana-hloko e fumaneha mona

Tlaleho ea Lintho tsa Khalase tse Phahameng tsa Borosilicate

| 密度 (Density) | 2.30g/cm² |

| 硬度 (Bothata) | 6.0′ |

| 弹性模量 (Elasticity Modulus) | 67KNmm – 2 |

| 抗张强度 (Tensile Strength) | 40 – 120Nmm – 2 |

| 泊松比 (Poisson Ratio) | 0.18 |

| 热膨胀系数 (20-400°C) (Coefficient of Thermal Expansion) | (3.3)*10`-6 |

| 导热率比热(90°C)(Specific Heat Conductivity) | 1.2W*(M*K`-1) |

| 折射率 (Refractive Index) | 1.6375 |

| 比热 (Specific Heat) (J/KG) | 830 |

| 熔点 (Melting Point) | 1320°C |

| 软化点 (Softening Point) | 815°C |

| 连续工作温度/使用寿命 (Mocheso o Tsoelang Pele oa ho Sebelisa/Bophelo ba Ts'ebeletso) | 150°C |

| ≥120000h(-60°C-150°C) | 200°C |

| ≥90000h(-60°C-200°C) | 280°C |

| ≥620000h(-60°C-280°C) | 370°C |

| ≥30000h | 520°C |

| ≥130000h | |

| 抗热冲击(Thermal Shock) | ≤350°C |

| 抗冲击强度(Impact Strength) | ≥7J |

| 主要化学成分%含量 (Main Chemical Composition % Content) | |

| SiO2 | 80.40% |

| Fe203 | 0.02% |

| Ti02 | 1.00% |

| B203 | 12.50% |

| Na20+K20 | 4.20% |

| FE | 0.02% |

| 耐水性 (Mamello ea Metsi) | HGB 1级 (HGB 1) |

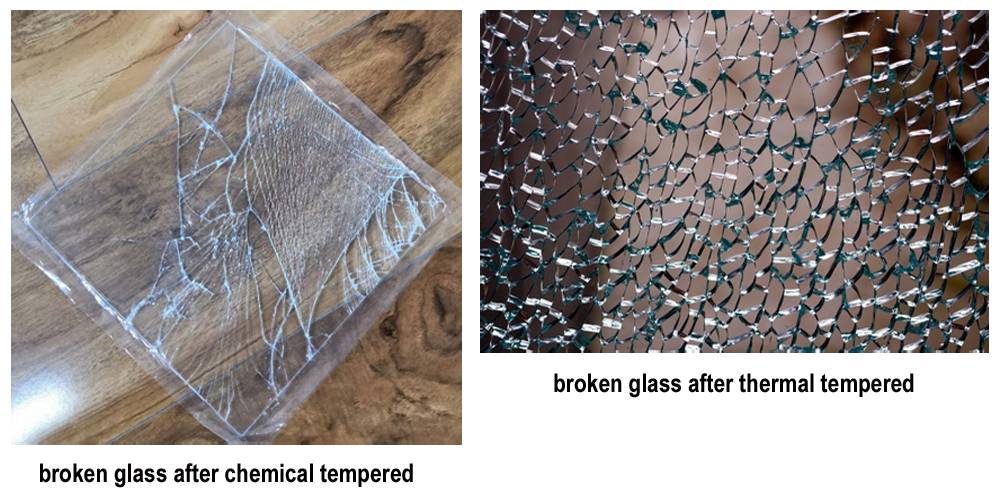

Khalase ea polokeho ke eng?

Khalase e halefileng kapa e tiileng ke mofuta oa khalase ea polokeho e sebetsoang ka mekhoa e laoloang ea mocheso kapa ea lik'hemik'hale ho eketsa

matla a eona ha a bapisoa le khalase e tloaelehileng.

Tempering e beha bokaholimo ba kantle khatellong le kahare khatellong.

Kakaretso ea Fektheri

HO ETA LE HO FUMANA MAIKUTLO HO BAREKI

Lisebelisoa tsohle tse sebelisitsoeng ke E DUMELANA LE ROHS III (PHETOHO EA EUROPE), ROHS II (PHETOHO EA CHAENA), REACH (PHETOHO EA HONA JOALE)

FEKTERI EA RŌNA

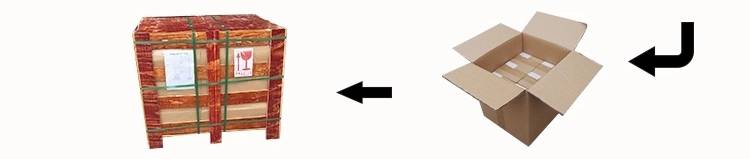

MOKHOA OA RŌNA OA TLHAHISO LE POKELO

Filimi e sireletsang ea Lamiant — Pakete ea k'hothone ea perela — Pakete ea pampiri ea Kraft

Mefuta e 3 ea khetho ea ho phuthela

Sephutheloana sa khese ea plywood kantle ho naha — Sephutheloana sa lebokose la pampiri kantle ho naha