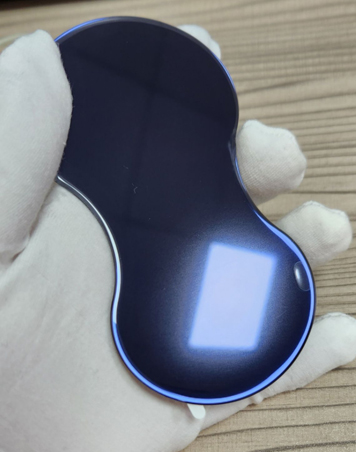

As a leading name in the custom glass panel customized industry, Saida Glass is proud to offer a range of plating services to our customers. In particular, we specialize in glass – a process that deposits thin layers of metal onto glass panel surfaces to give it an attractive metallic color or metallic finish.

There are several benefits to adding color to glass panel surface by using electroplating.

Firstly, this process allows for a greater range of colors and finishes than other methods such as traditional painting or staining. Electroplating can be produced in a wide range of metallic or iridescent colors, from gold and silver to blue, green and purple, and can be customized for individual projects or applications.

Secondary, another advantage of electroplating is that the resulting color or finish is more durable and resistant to wear and tear than painted or printed glass. This makes it ideal for high-traffic or high-use areas such as commercial buildings, shopping centers and hotels.

In addition, electroplating can be used to enhance the heat resistance and UV resistance of glass panel, increasing its service life and suitability for outdoor applications.

However, electroplating also has some potential disadvantages. First, the electroplating process is very expensive, especially for large or curved shaped glass. Material, equipment, and labor costs involved in the plating process can increase, which may limit its suitability for certain applications. In addition, electroplating sometimes produces hazardous waste that must be carefully disposed to minimize environmental impact.

Despite of these challenges, we believe the benefits of glass plating far outweigh the costs. Our skilled technicians use the latest equipment and techniques to ensure that the high quality plated glass we produce are not only visually stunning, but also durable.

In conclusion, we firmly believe that glass electroplating is a valuable addition to the glass industry, offering a range of colors and finishes not achievable by other methods. While there are some drawbacks to this process, we at Saida Glass are committed to using it responsibly and sustainably, providing our customers with reliable and visually astonishing glass products.

Post time: Apr-25-2023