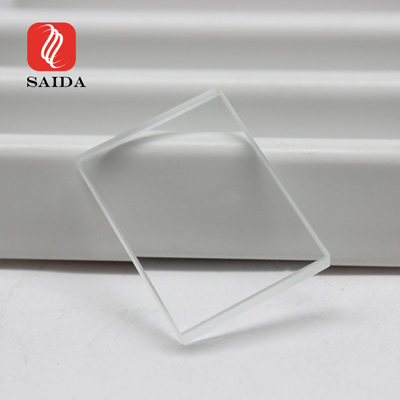

IK09 10mm Ultra Transparent Borosilicate Glass Panel yemwenje ye LED

ZVINHU ZVINHU

– 3.3 Kuwanda kweThermal Coefficient

- Kusapisa zvakanyanya kana paine makemikarikugadzikana

–Inodzivirira kukwenya kwakanyanya, isingapindi mvura uye inodzivirira murazvo

–Kutsetseka kwakakwana uye kutsvedzerera

–Vimbiso yezuva rekutumira panguva yakakodzera

–Kubvunzana kwemunhu mumwe nemumwe uye nhungamiro yehunyanzvi

–Chimiro, saizi, finsh & dhizaini zvinogona kugadziriswa sekukumbira

–Zvinodzivirira kupenya/Zvinodzivirira kupenya/Zvinodzivirira kupenya kweminwe/Zvinorwisa utachiona zviripo pano

YakakwiriraGirazi reBorosilicateMushumo Wezvinhu

| 密度 (Density) | 2.30g/cm² |

| 硬度 (Kuoma) | 6.0' |

| 弹性模量 (Elasticity Modulus) | 67KNmm – 2 |

| 抗张强度(Tensile Strength) | 40 – 120Nmm – 2 |

| 泊松比(Poisson Ratio) | 0.18 |

| 热膨胀系数 (20-400°C) (Coefficient of Thermal Expansion) | (3.3)*10`-6 |

| 导热率比热(90°C)(Specific Heat Conductivity) | 1.2W*(M*K`-1) |

| 折射率 (Refractive Index) | 1.6375 |

| 比热 (Specific Heat) (J/KG) | 830 |

| 熔点 (Melting Point) | 1320°C |

| 软化点 (Softening Point) | 815°C |

| 连续工作温度/使用寿命 (Kuramba Kuchibata Tembiricha/Hupenyu Hwebasa) | 150°C |

| ≥120000h(-60°C-150°C) | 200°C |

| ≥90000h(-60°C-200°C) | 280°C |

| ≥620000h(-60°C-280°C) | 370°C |

| ≥30000h | 520°C |

| ≥130000h | |

| 抗热冲击(Thermal Shock) | ≤350°C |

| 抗冲击强度(Impact Strength) | ≥7J |

| 主要化学成分%含量 (Main Chemical Composition % Content) | |

| SiO2 | 80.40% |

| Fe203 | 0.02% |

| Ti02 | 1.00% |

| B203 | 12.50% |

| Na20+K20 | 4.20% |

| FE | 0.02% |

| 耐水性 (Kushivirira Kwemvura) | HGB 1级 (HGB 1) |

Chii chinonzi Borosilicate Glass?

Girazi reBorosilicate imhando yegirazi rine silica neboron trioxide sezvinhu zvikuru zvinoumba girazi. Magirazi eBorosilicate anozivikanwa nekuve nema coefficients akaderera ekuwedzera kwekupisa (≈3 × 10⁻⁶ K⁻¹ pa20 °C), zvichiita kuti arambe kupisa kupfuura mamwe magirazi akajairika. Girazi rakadaro harina simba rekupisa zvakanyanya uye rinogona kutsungirira kusiyana kwekupisa pasina kupwanyika kweinenge 165 °C (297 °F). Rinowanzo shandiswa pakuvaka mabhodhoro nemaflasks e reagent pamwe nemwenje, zvemagetsi uye zvekubika.

Maitiro Ekugadzira

ZVIMWE ZVINOTAURWA NEFEKTORI

KUSHANYIRA KWEVATENGI & MHINDURO

Zvinhu zvese zvinoshandiswa ndezve INOTEVERA NE ROHS III (VERSION YEKUEUPENYU), ROHS II (VERSION YECHINA), REACH (VERSION YAZVINO)

FEKITARI YEDU

Mutsetse wedu wekugadzira & Dura rekuchengetedza

Firimu rekudzivirira rinonamira — Kurongedza donje rePearl — Kurongedza bepa reKraft

Sarudzo yemhando nhatu dzekuputira

Tumira kunze plywood case pack — Tumira kunze paper carton pack