Ngenkathi sisebenzisa ifilosofi yenkampani ethi “Client-Oriented”, indlela yokuphatha esezingeni eliphezulu edingayo, imikhiqizo emisha yokukhiqiza kanye nabasebenzi abaqinile be-R&D, sihlala sinikeza izimpahla ezisezingeni eliphezulu, izixazululo ezinhle kakhulu kanye namanani okuthengisa anamandla e-Factory 3D Printer Material Tempered Borosilicate Glass Plates, Sinempahla enkulu yokugcwalisa izidingo nezidingo zamakhasimende ethu.

Ngenkathi sisebenzisa ifilosofi yenkampani ethi “Iqondiswe Kumakhasimende”, indlela yokuphatha esezingeni eliphezulu edingayo, imikhiqizo emisha yokukhiqiza kanye nabasebenzi abaqinile be-R&D, sihlala sinikeza izimpahla ezisezingeni eliphezulu, izixazululo ezinhle kakhulu kanye namanani okuthengisa anamandla.Ingilazi ye-Borosilicate ephezulu yaseShayina, Ishubhu Elicacile, Sihlala sinamathela kumgomo othi “ubuqotho, ikhwalithi ephezulu, ukusebenza kahle okuphezulu, ukusungula izinto ezintsha”. Ngeminyaka eminingi yemizamo, manje sesisungule ubudlelwano bebhizinisi obunobungane nobuzinzile namakhasimende omhlaba wonke. Siyakwamukela noma yimiphi imibuzo yakho kanye nokukhathazeka ngezixazululo zethu, futhi siqinisekile ukuthi sizokunikeza lokho kanye okufunayo, njengoba sihlala sikholelwa ukuthi ukwaneliseka kwakho yimpumelelo yethu.

IZICI

– 3.3 Isilinganiso Sokwanda Kokushisa

- Ukumelana nokushisa okuphezulu ngamakhemikhaliukuzinza

–Imelana nokuklwebheka kakhulu futhi ayingeni manzi futhi ayimelani nomlilo

–Ukuthamba okuphelele nokushelela

–Isiqinisekiso sosuku lokulethwa ngesikhathi

–Ukubonisana komuntu ngamunye kanye nesiqondiso sobungcweti

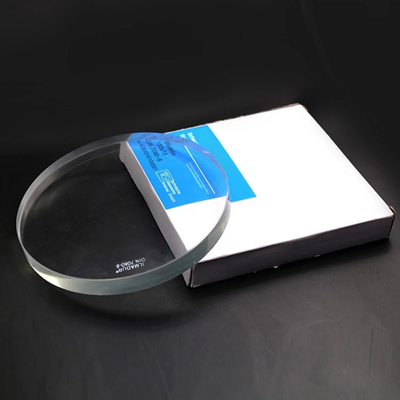

–Ukuma, usayizi, i-finsh kanye nomklamo kungenziwa ngezifiso njengesicelo

–Okulwa nokukhanya/Okulwa nokukhanya/Okulwa nokunyathelisa iminwe/Okulwa namagciwane kuyatholakala lapha

Umbiko Wezinto Zengilazi Ezine-Borosilicate Ephakeme

| 密度 (Ukuminyana) | 2.30g/cm² |

| 硬度 (Ukuqina) | 6.0' |

| 弹性模量 (I-Elasticity Modulus) | 67KNmm – 2 |

| 抗张强度(Amandla Aqinile) | 40 – 120Nmm – 2 |

| 泊松比(Poisson Ratio) | 0.18 |

| 热膨胀系数 (20-400°C) (I-Coefficient of Thermal Expansion) | (3.3)*10`-6 |

| 导热率比热(90°C)(I-Specific Heat Conductivity) | 1.2W*(M*K`-1) |

| 折射率 (Refractive Index) | 1.6375 |

| 比热 (Ukushisa Okuthile) (J/KG) | 830 |

| 熔点 (Melting Point) | 1320°C |

| 软化点 (Iphuzu Lokuthambisa) | 815°C |

| 连续工作温度/使用寿命 (Izinga Lokushisa Eliqhubekayo/Impilo Yesevisi) | 150°C |

| ≥120000h(-60°C-150°C) | 200°C |

| ≥90000h(-60°C-200°C) | 280°C |

| ≥620000h(-60°C-280°C) | 370°C |

| ≥30000h | 520°C |

| ≥130000h | |

| 抗热冲击(Thermal Shock) | ≤350°C |

| 抗冲击强度(Amandla Omthelela) | ≥7J |

| 主要化学成分%含量 (Ukwakheka Kwekhemikhali Eyinhloko % Okuqukethwe) | |

| I-SiO2 | 80.40% |

| Fe203 | 0.02% |

| I-Ti02 | 1.00% |

| B203 | 12.50% |

| I-Na20+K20 | 4.20% |

| FE | 0.02% |

| 耐水性 (Ukubekezelela Amanzi) | I-HGB 1级 (HGB 1) |

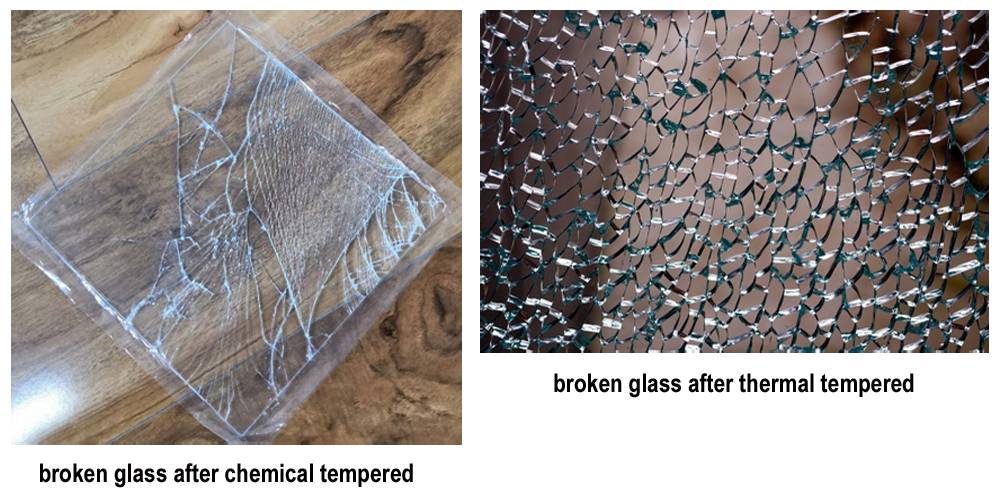

Iyini ingilazi yokuphepha?

Ingilazi ethambile noma eqinile uhlobo lwengilazi yokuphepha ecutshungulwa ngokwelashwa okulawulwayo kokushisa noma kwamakhemikhali ukuze kwandiswe

amandla ayo uma eqhathaniswa nengilazi evamile.

Ukushisa kubeka ubuso bangaphandle ekucindezelweni kanye nengaphakathi ekucindezelweni.

ISIBUYEKEZO SEFEKTHI

UKUVAKASHA KWAMAKHASIMENDE NOKUPHENDULA

Zonke izinto ezisetshenzisiwe ziyi KUYAHAMBISANA NE-ROHS III (INGUQULO YASE-EUROPE), ROHS II (INGUQULO YASE-CHINA), REACH (INGUQULO YAMANJE)

IFIKITHI YETHU

UMZILA WETHU WOKUKHIQIZA NESITOBHA SOKUGCINA

Ifilimu yokuvikela evikelayo — Ukupakisha ukotini weparele — Ukupakisha iphepha lobuciko

Ukukhetha Okuthathu Kokugoqa

Thumela iphakethe lesikhwama se-plywood — Thumela iphakethe lebhokisi lephepha