Àwọn Ẹ̀yà ara

– 3.3 Isodipupo ti Imugboroosi Ooru

- Idaabobo iwọn otutu giga pẹlu kemikaliiduroṣinṣin

–Ko ni ibere pupọ, ko ni omi ati ko ni ina

–Pípé títẹ́jú àti dídánmọ́rán

–Idaniloju ọjọ ifijiṣẹ akoko

–Ìgbìmọ̀ràn àti ìtọ́sọ́nà ọ̀jọ̀gbọ́n kan sí ọ̀kan

–Apẹrẹ, iwọn, ipari ati apẹrẹ le ṣe adani bi ibeere

–Àwọn ohun tí ó ń dènà ìmọ́lẹ̀/Ìdínà àtúnṣe/Ìdínà ìka/Ìdínà àwọn kòkòrò àrùn wà níbí

Ìròyìn Ohun èlò Gíláàsì Borosilicate Gíga

| 密度 (Ìwúwo) | 2.30g/cm² |

| Lile (lile) | 6.0' |

| 弹性模量(Elasticity Modulus) | 67KNmm – 2 |

| 抗张强度( (Agbara Fifẹ) | 40 – 120Nmm – 2 |

| 泊松比(Ratio Poisson) | 0.18 |

| 热膨胀系数(20-400°C) | (3.3)*10`-6 |

| 导热率比热(90°C)(Imudara Ooru kan pato) | 1.2W*(M*K`-1) |

| 折射率(Atọka Refractive) | 1.6375 |

| 比热(Ooru Kan pato) (J/KG) | 830 |

| 熔点 (Okooko Iyọ) | 1320°C |

| 软化点 (Omi Asọ) | 815°C |

| 连续工作温度/使用寿命 (Iwọn otutu Iṣiṣẹ tẹsiwaju / Igbesi aye Iṣẹ) | 150°C |

| ≥120000h(-60°C-150°C) | 200°C |

| ≥90000h(-60°C-200°C) | 280°C |

| ≥620000h(-60°C-280°C) | 370°C |

| ≥30000h | 520°C |

| ≥130000h | |

| 抗热冲击(Thermal Shock) | ≤350°C |

| 抗冲击强度(Agbara Ipa) | ≥7J |

| 主要化学成分%含量(Akopọ Kemikali akọkọ% Akoonu) | |

| SiO2 | 80.40% |

| Fe203 | 0.02% |

| Ti02 | 1.00% |

| B203 | 12.50% |

| Na20+K20 | 4.20% |

| FE | 0.02% |

| 耐水性( Ifarada omi) | HGB 1 ni (HGB 1) |

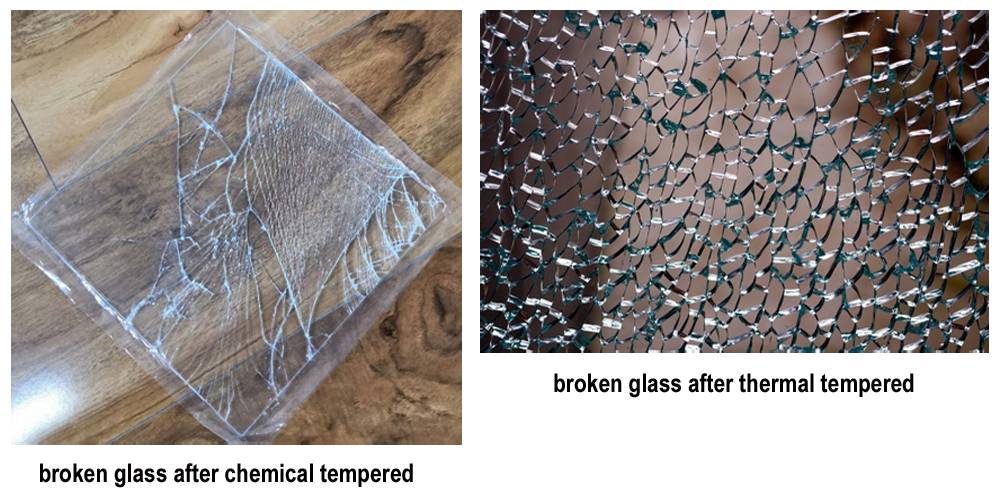

Kí ni gilasi aabo?

Gilasi ti o ni iwọn otutu tabi ti o lagbara jẹ iru gilasi aabo ti a ṣe ilana nipasẹ awọn itọju ooru tabi kemikali ti a ṣakoso lati mu pọ si

Agbára rẹ̀ ní ìfiwéra pẹ̀lú gilasi déédéé.

Tempering fi awọn oju ita sinu titẹ ati inu sinu titẹ.

ÀKÓKÒ ÌṢẸ́ṢẸ̀

ÌBẸ̀WÒ ÀTI ÈSÍ ÀWỌN ONÍBÀÁRÀ

Gbogbo àwọn ohun èlò tí a lò ni Ó bá ROHS III (Ẹ̀dà Yúróòpù), ROHS II (Ẹ̀dà Ṣáínà), REACH (Ẹ̀dà Lọ́wọ́lọ́wọ́) mu

Ilé-iṣẹ́ Wa

ÌṢẸ̀DÁ ÀTI ÌKÓJỌ WA

Fíìmù ààbò tó ń lamian — Àpò owú Pearl — Àpò ìwé Kraft

Irú àṣàyàn ìdìpọ̀ mẹ́ta

Gbé àpò plywood jáde — Gbé àpò páálí ìwé jáde