HORDHAC ALAABTA

- Iska caabin heerkul sare

- Iska caabbinta daxalka

- Xasillooni kuleyl oo wanaagsan

- Waxqabadka gudbinta iftiinka wanaagsan

- Waxqabadka dahaarka korontadu waa wanaagsan yahay

-La-talin hal-hal ah iyo hagitaan xirfadeed

-Qaabka, cabbirka, fin & naqshadaynta waxaa loo habeyn karaa sida loogu baahdo

-Ka-hortagga dhalaalka/Ka-hortagga milicsiga/Ka-hortagga faraha/Ka-hortagga jeermiska ayaa laga heli karaa halkan

Waa maxay Quartz Glass?

Galaas quartz ahwaa muraayad tiknoolajiyadeed oo gaar ah oo laga sameeyay silicon dioxide iyo walxo aasaasi ah oo aad u wanaagsan.

| Magaca Badeecada | Tuubo Quartz ah |

| Alaab | 99.99% galaas quartz ah |

| Dhumucda | 0.75mm-10mm |

| Dhexroorka | 1.5mm-450mm |

| Heerkulka Shaqada | 1250 ℃, heerkulka barta jilicsanaanta waa 1730°C. |

| Dhererka | ODM, sida waafaqsan shuruudaha macaamiisha |

| Xirmo | Ku xiran sanduuqa kartoonka dhoofinta caadiga ah ama kiis alwaax ah |

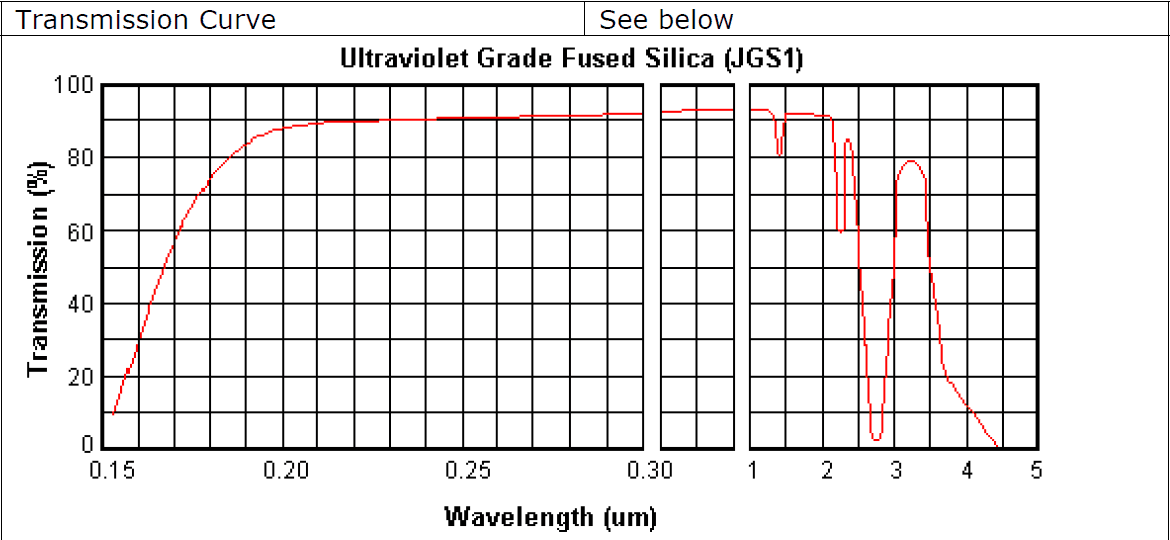

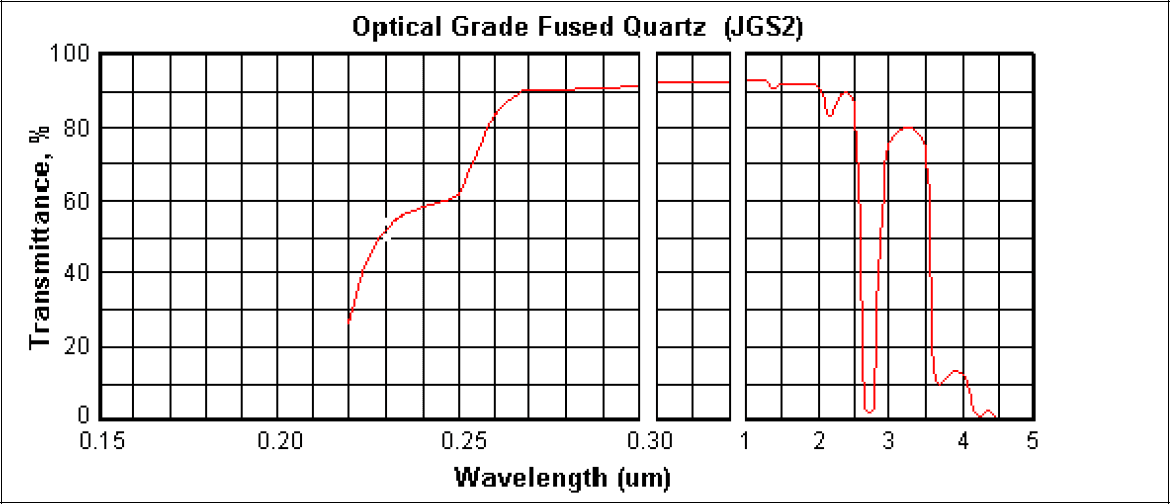

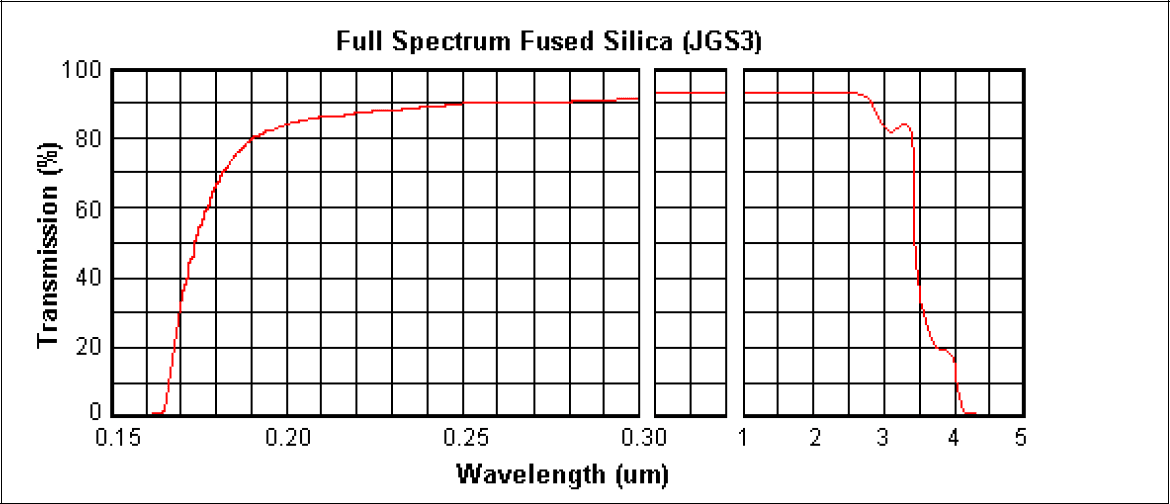

| Halbeegga/Qiimaha | JGS1 | JGS2 | JGS3 |

| Cabbirka ugu Badan | <Φ200mm | <Φ300mm | <Φ200mm |

| Kala duwanaanshaha Gudbinta (Saamaynta gudbinta dhexdhexaadka ah) | 0.17 ~ 2.10um (Tavg>90%) | 0.26 ~ 2.10um (Tavg>85%) | 0.185 ~ 3.50um (Tavg>85%) |

| Iftiinka (sida 254nm) | Dhab ahaantii Bilaash ah | VB xooggan | VB xooggan |

| Habka Dhalmada | CVD-ga Synthetic-ga ah | Oxygen-hydrogen dhalaalid | Koronto dhalaalid |

| Codsiyada | Substrate-ka laysarka: Daaqadda, muraayadda, muraayad, muraayad… | Semiconductor iyo sare daaqadda heerkulka | IR & UV substrate-ka |

DULUCDA WARSHADAHA

BOOQASHADA MACMIILKA IYO FEEDHAYNTA

Dhammaan Agabka la isticmaalay waa U HOGAANSAN ROHS III (Nooca Yurub), ROHS II (Nooca Shiinaha), GAARSI (Nooca Hadda)

Warshadeenna

KHAADKA SOO SAARKA IYO BAKHAARKAYGA

Filim ilaalin ah oo lamian ah — Baakad suuf ah oo luul ah — Baakad warqad Kraft ah

3 NOOC OO DOORASHADA DABAAQA AH

Dhoofi baakadda kiiska alwaaxa - Dhoofi baakadda kartoonka warqadda ah