GABATARWAR KAYAYYAKI

- Fiye da kashi 96% na watsawa don allon taɓawa

–Mai jure karce sosai da kuma hana ruwa

–Tsarin musamman tare da tabbacin inganci

–Cikakken laushi da santsi

–Tabbatar da ranar isarwa da lokaci

–Shawarwari ɗaya-ɗaya da kuma jagorar ƙwararru

–Ana maraba da ayyukan keɓancewa don siffa, girma, ƙarewa & ƙira

–Ana samun maganin hana haske/hana haske/hana zanen yatsa/hana ƙwayoyin cuta a nan

| Nau'in Samfuri | Gilashin Murfi Mai Zafi Mai Inci 12 na 1mm don Nunin TFT | |||||

| Albarkatun kasa | Gilashin Fari/Soda Lemun tsami/Ƙaramin ƙarfe | |||||

| Girman | Girman za a iya keɓance shi | |||||

| Kauri | 0.33-12mm | |||||

| Mai jurewa | Tsarin Zafin Jiki/Sinadari Mai Tsaftacewa | |||||

| Edgework | Faɗin Ƙasa (Flat/Fercil/Bevelled/Chamfer Edge suna samuwa) | |||||

| Rami | Zagaye/Murabba'i (Rami mara tsari yana samuwa) | |||||

| Launi | Baƙi/Fari/Azurfa (har zuwa yadudduka 7 na launuka) | |||||

| Hanyar Bugawa | Allon Siliki na Al'ada/Allon Siliki Mai Zafi Mai Tsayi | |||||

| Shafi | Anti-Glaring | |||||

| Mai hana nuna haske | ||||||

| Hana Yatsa | ||||||

| Maganin Karce | ||||||

| Tsarin Samarwa | Cut-Edge Polish-CNC-Clean-Print-Clean-Inspect-Pack | |||||

| Siffofi | Maganin ƙazantar fata | |||||

| Mai hana ruwa | ||||||

| Hana yatsan hannu | ||||||

| Hana gobara | ||||||

| Mai jure karce mai ƙarfi | ||||||

| Maganin ƙwayoyin cuta | ||||||

| Kalmomi Masu Mahimmanci | Gilashin Murfi Mai Zafi Don Nuni | |||||

| Mai Sauƙin Tsaftace Gilashi | ||||||

| Mai Hankali Mai Kauri Gilashin Mai Kauri Mai Ruwa | ||||||

Menene Gilashin Siliki?

Gilashin da aka yi da siliki, wanda kuma ake kira da buga siliki ko gilashin bugawa mai kariya, ana yin sa ne ta hanyar canja wurin hoton allon siliki zuwa gilashin sannan a sarrafa shi ta hanyar tanda mai dumama a kwance. Kowane lite ana buga shi da allon tare da tsarin da ake so da launin frit enamel na yumbu. Ana iya goge frit ɗin yumbu ta hanyar siliki a kan gilashin a cikin ɗaya daga cikin tsare-tsare uku na yau da kullun - dige-dige, layuka, ramuka - ko kuma a cikin aikace-aikacen cikakken rufewa. Bugu da ƙari, ana iya kwafi zane-zane na musamman cikin sauƙi akan gilashin. Dangane da tsarin da launi, ana iya sanya gilashin lite mai haske, mai haske ko mara haske.

Gilashin da aka ƙarfafa ta hanyar sinadarai wani nau'in gilashi ne wanda ke ƙara ƙarfi sakamakon aikin sinadarai bayan samarwa. Idan ya karye, har yanzu yana karyewa a cikin dogayen ramuka masu kaifi kamar gilashin iyo. Saboda wannan dalili, ba a ɗaukarsa a matsayin gilashin aminci ba kuma dole ne a yi masa laminate idan ana buƙatar gilashin aminci. Duk da haka, gilashin da aka ƙarfafa ta hanyar sinadarai yawanci ya ninka ƙarfin gilashin iyo sau shida zuwa takwas.

Ana ƙarfafa gilashin ta hanyar sinadarai ta hanyar tsarin kammala saman. Ana nutsar da gilashin a cikin baho mai ɗauke da gishirin potassium (yawanci potassium nitrate) a zafin 300 °C (572 °F). Wannan yana sa a maye gurbin ions ɗin sodium a saman gilashin da ions ɗin potassium daga ruwan wanka.

Waɗannan ion ɗin potassium sun fi ion ɗin sodium girma, don haka suna ratsawa cikin gibin da ƙananan ion ɗin sodium suka bari lokacin da suka ƙaura zuwa ga maganin potassium nitrate. Wannan maye gurbin ion ɗin yana sa saman gilashin ya kasance cikin matsi kuma zuciyarsa tana cikin damuwa mai ramawa. Matsi na saman gilashin da aka ƙarfafa ta hanyar sinadarai na iya kaiwa har zuwa 690 MPa.

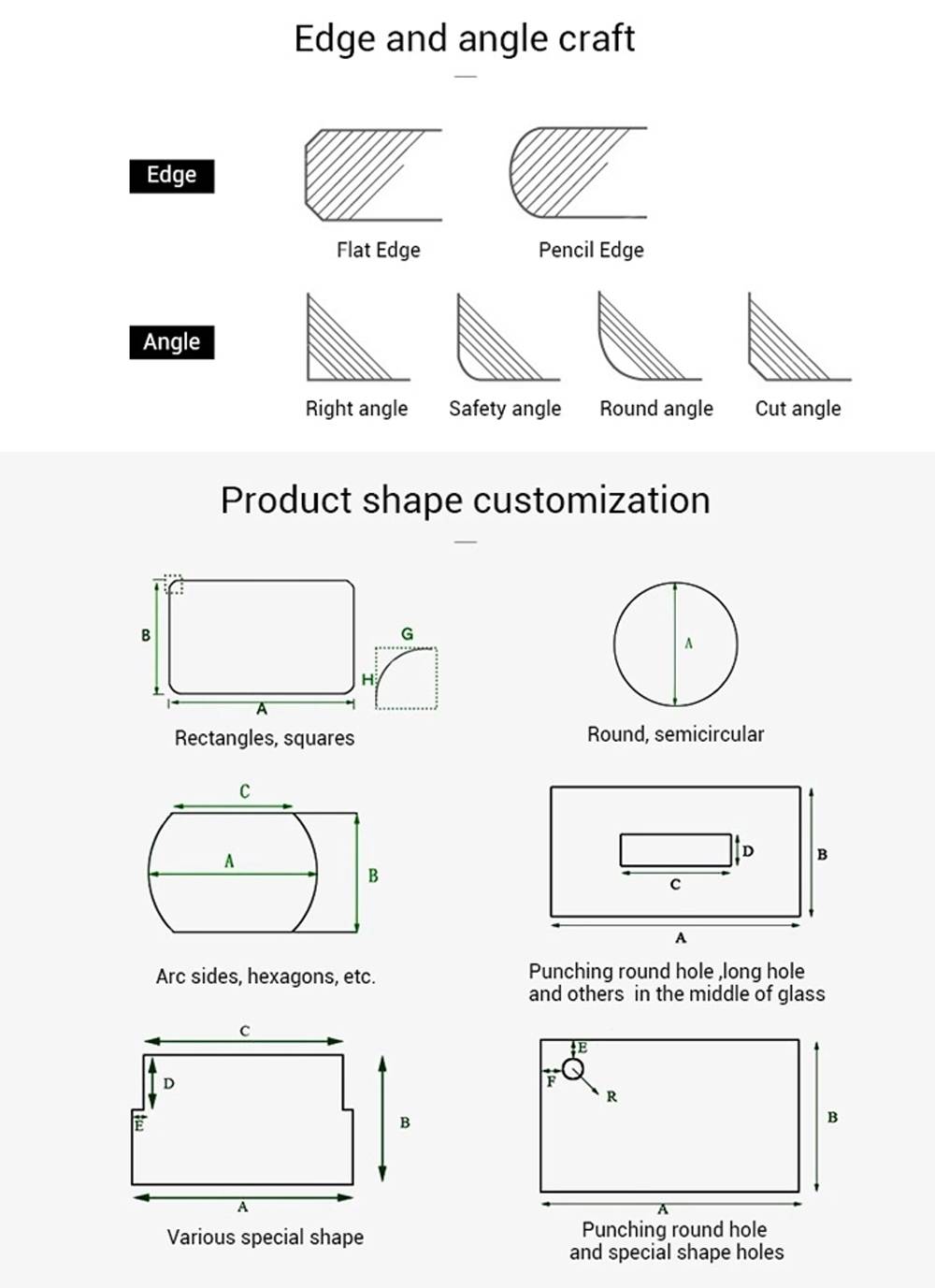

Aikin Gefen & Kusurwa & Siffa

ALBARKAR KAYAYYAKI

| Injin Yankewa ta atomatik | Girman da ya fi girma: 3660*2440mm |

| CNC | Girman da ya fi girma: 2300*1500mm |

| Niƙa da Haɗa Gefen | Girman da ya fi girma: 2400*1400mm |

| Layin Samarwa ta atomatik | Girman da ya fi girma: 2200*1200mm |

| Tanderu Mai Zafi | Girman da ya fi girma: 3500*1600mm |

| Tanda Mai Zafin Sinadarai | Girman da ya fi girma: 2000*1200mm |

| Layin Shafi | Girman da ya fi girma: 2400*1400mm |

| Layin Murhu Mai Busasshe | Girman da ya fi girma: 3500*1600mm |

| Layin Marufi | Girman da ya fi girma: 3500*1600mm |

| Injin Tsaftacewa ta Atomatik | Girman da ya fi girma: 3500*1600mm |

ZIYARAR KWANO DA RA'AYOYIN MABIYA

Masana'antarmu

LAYIN MASU SAMFURA DA RUBUTU

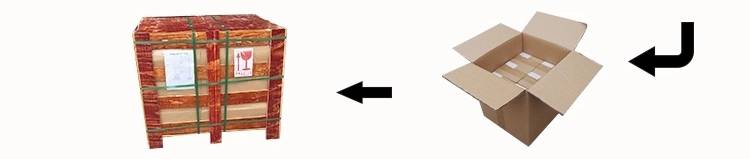

Fim ɗin kariya mai lamiant — Fakitin auduga na lu'u-lu'u — Fakitin takarda na Kraft

IRIN ZAƁIN NAƊAƁAƁEN NAƊAKI 3

Fitar da fakitin akwati na plywood — Fitar da fakitin kwali na takarda